Stucco and manufactured stone have been used in the building industry for ages. These claddings are well known, and well used for their leading properties in fire resistance, durability, and aesthetics. In fact, according to the Census Bureau’s recent Survey of Construction, 25% of homes built in the US in 2017 used stucco cladding; second only to vinyl, which was used in 27% of homes. This number is predicted only to increase, with stucco usage expected to continue to grow across the globe, especially in North America.

Although it is evident stucco is a strong choice for several reasons, many builders are still scratching their heads when it comes to tackling their biggest challenge with this type of finish – moisture. Moisture is a critical concern for stucco and manufactured stone homes. Without the right protection, uncontrolled moisture can lead to mold, wall rot, and decay, and eventually have an impact on both the aesthetics and structural integrity of the home. Though weather protection is a concern for any type of building, professionals using stucco cladding should be taking even greater care to ensure their homes are well prepared for the road ahead.

What’s so unique about stucco and manufactured stone?

To start, we know that stucco is considered a reservoir cladding, meaning that it can absorb and store rainwater. It’s part of a group of materials such as brick that will hold more water than others. On top of this, as Building Science expert Dr. Joe Lstiburek explains, there are several factors working together that contribute to the increased challenges we’re seeing:

“Stucco goes back thousands of years, but the problem is that we’ve changed the way we do stucco. First of all, we put the stucco over highly insulated assemblies: we didn’t used to do that. We also put stucco over engineered wood products such as OSB, when we used to put it over plywood and boards. We’ve also changed the physical characteristics of the stucco. Today’s stuccos don’t breathe as well as the old stuccos. These changes have led to significant problems with stucco, particularly in places where it rains a great deal. And as a result, we have to change the way we apply stucco today.”

Moisture problems are a two-way street

Most professionals understand that it is critical to keep water and dampness from getting into a building, therefore avoiding moisture that moves through the wall from the outside. This means putting the right measures in place to keep any moisture from penetrating the system.

However, it’s just as critical to ensure that moisture that originates within the walls is able to escape. Trapped moisture can cause severe issues that lead to mold and, unfortunately, it’s a problem that may not be evident until it is too late. For example, the commonly known “stucco tears,” stains that appear under installations such as windows, are a clear sign that moisture has started to create damage to the home. When left untreated, these issues are very likely to have a dramatic impact on the overall structural integrity and safety of the home.

According to Lstiburek, “Things have been getting wet forever. What’s different is that things are staying wet longer, and the things that are staying wet longer aren’t as tough or robust and able to resist the moisture as the traditional materials in the past. As a result, we’re beginning to see more mold, we’re beginning to see more decay, we’re seeing loss of strength, we’re seeing dimensional changes, shifting, cracking. These things we didn’t see before.”

What’s the best solution?

There are several steps vital to protecting homes from incidental moisture. These include measures such as proper flashing around windows and doors, and proper application of the stucco itself. But, as Lstiburek explains, one of the most important ways to get ahead of moisture protection for stucco homes is to create a gap within the wall system.

“The secret is to provide a gap between the stucco and the substrates. We need an airspace between stucco and the rest of the wall. If we have the right kind of space, stucco will last hundreds of years.

“A gap provides two important functions. One is to allow outward drying through a vapor-open water- and air-control layer, and it also provides prevention of inward wetting as a result of moisture coming out of a reservoir cladding.”

When it comes to creating the gap, various methods and materials exist that can be used to separate the cladding from the substrates. However, most building experts would agree that using a dimpled membrane, or ventilated rainscreen, is the most effective moisture protection approach.

Drain, dry, & save time

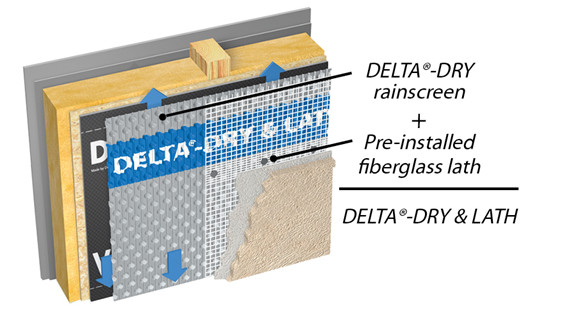

Dörken’s DELTA®-DRY & LATH helps builders protect their stucco and manufactured stone homes. The DELTA®-DRY & LATH system leverages the proven technology of DELTA®-DRY, the first channeled polyethylene sheeting that dries and drains, and that can’t be penetrated by moisture, neither liquid nor vapor.

DELTA®-DRY & LATH not only blocks solar-driven moisture from the outside, but also works to get rid of any moisture that exists on the inside. On top of this, as a 2-in-1 solution, it combines the DELTA®-DRY rainscreen with a fiberglass lath for a complete, one-step system.

Using alkali-resistant fiberglass instead of metal addresses another common stucco challenge when it comes to rust and visual staining. Metals not only create issues with aesthetic appearances in stucco and manufactured stone homes, they also leave structures susceptible to cracks, leaks, falling stones, and overall moisture intrusion and damage. Fiberglass is chemical and corrosion resistant, and won’t rust over time, meaning DELTA®-DRY & LATH will remain stable, protecting a building’s integrity well into the future.

Protecting what matters most

When stucco and manufactured stone homes are built correctly, they can provide many benefits for homeowners, including energy efficiency, sustainability, durability, and increased fire protection. However, when moisture protection is left unaddressed, the effects can be detrimental, both for the homeowner and the builder. Getting ahead of water and dampness is the only way to ensure new stucco and manufactured stone homes live out their full potential.

About the author

Peter Barrett is the Product Manager and Marketing Manager for Dörken Systems Inc. and has been with the company for over 12 years. His involvement with the design community and building materials industry spans over 25 years. Peter holds a BA (Hons.) from Queen’s University and an MBA from Wilfrid Laurier University, and currently serves on the Board of Directors for the Air Barrier Association of America (ABAA) and on the Audit Committee. Additionally, he serves on committees for the Rainscreen Association in North America (RAiNA). Peter has also contributed to The Construction Specifier, Construct Canada, Tunnel Business, Waterproofing Magazine and Masonry Magazine.www.dorken.com