Why This Client Chose the X-Bracket System

When our client, Brad from Texas, first came to us, he was wrestling with a common conundrum in high-performance homebuilding: his existing wall assemblies weren’t delivering the thermal performance, moisture control, or durability he wanted, and he was facing rising costs and labor headaches with traditional retrofit methods.

Brad’s home has been growing with his family over the decades. Initially a single level, brick 1970’s home, they added a garage, then a master bedroom suite, bathroom renovations, additional bedrooms for children as their family grew, finally a bigger kitchen. The renovations were planned and worked well until about a decade ago when a contractor didn’t seal the new second story renovation well and they started experiencing leaks around the roof additions and along the seam of the first and second story. This unfortunately turned the renovations and expansions into repairs and ripping out large sections of their home from water damage. The solution? Their family home needed a new roof and brick wall repairs.

With a growing passion for passive home innovation, Brad ventured into the Build Show in Texas and met the InSoFast Team. Initially interested in their EPS Panels, he switched his research to the new product in development, The X-Bracket System, and discovered it was a solution for the retrofit challenge he needed to accomplish. “I thought this would be genius because this old house has been patched together and getting a good air seal will be difficult because there are not many flat surfaces on the wall. When I saw I could put this bracket on and then closed cell spray foam the whole house to make essentially an igloo or a Yeti cooler I decided this would be the perfect solution. The foam will act as a strong water and air barrier and the bracket allowed him to create a smooth surface on his wavy walls.” This solution, of enclosing his existing home in a new exterior, allowed Brad to “save a ton of money to get to the same goal.”

This transformation — from frustration and inefficiency to confidence and performance — is exactly what the X-Bracket System was built for.

Before Photo

The X-Bracket System installed with fluid applied WRB

After Photo

From Story to Proof: What Mark’s Experience Shows

Looking back at Brad’s journey, several design-to-performance wins stand out.

- Installation Ease & Speed: Because X-Brackets fastened cleanly to his existing sheathing and required no complex framing, his team (which included one experienced framer and two helpers) completed the exterior-insulation retrofit quickly— a dramatic reduction compared to what a traditional retrofit (rigid foam + structural screws + furring + cladding) would have taken.

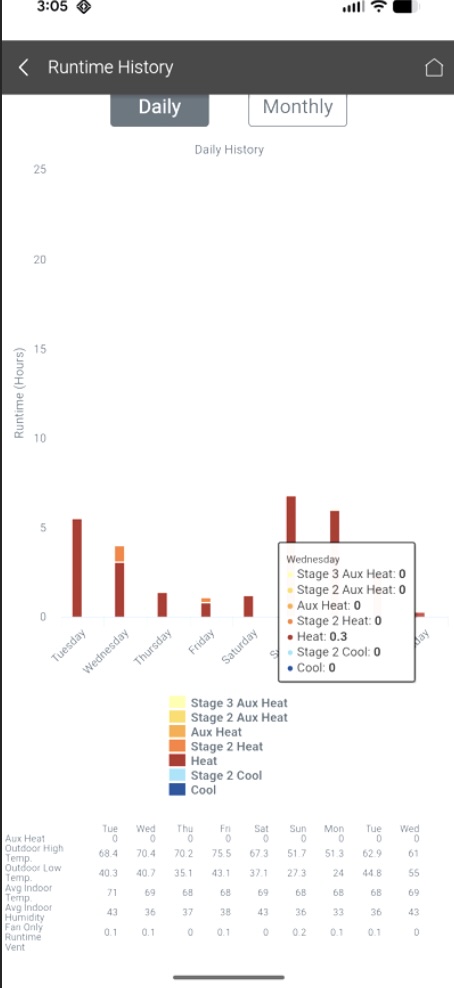

- Thermal Comfort Gains: Within a few days of finishing the exterior insulation and cladding, Brad reported more stable indoor temperatures, fewer drafts, and reduced reliance on heating — even when outdoor temps dipped. The Blower Test on the home went from a score of 13 ACH/50 down to an improved score of 1.7 ACH/50 with the continuous insulation, new doors and windows!

- For example, on one day, the high temp was 61 and they had the heat set to 69 degrees. The indoor temp stayed at 71 allowing them to maintain over a 10 degree delta from outside!

- Another evening their HVAC only ran 20 minutes after midnight while the outside temperatures overnight were in the 40’s.

-

Moisture Confidence: By combining continuous spray foam insulation with the ventilated rainscreen behind cladding, he felt comfortable the assembly had robust moisture control and drying potential — a key concern given Texas’ seasonal swings and freeze-thaw cycles.

-

Material & Labor Savings: Compared to other high-end building envelopes, the X-Bracket System has fewer components and is easily installed and does not require cross-trade training.

For builders working in climates like Texas — where temperature swings, moisture exposure, and energy cost pressures all collide — this kind of real-world performance makes a strong case for the X-Bracket System in high-performance and retrofit builds.

What Is the X-Bracket System? A CI Tool Built for Builders

At its core, the X-Bracket System is a matrix of thermally broken standoff brackets which serve as the skeleton for a continuous insulation (CI) layer installed on exterior walls, roofs, basements, floors and even shipping containers. The system is designed to accept closed-cell spray foam or blown-in (or loose-fill) insulation, over which standard furring strips and cladding can be attached.

Unlike traditional insulation systems which often create thermal bridges — conductive paths through cladding attachments undermine the insulation’s performance — the X-Bracket System is engineered to eliminate those. In other words: continuous insulation with zero thermal bridging.

Further, the brackets are non-conductive and manufactured from materials that won’t rust, rot, mold, or decay — which means long-term durability even under challenging climate, moisture, or weather conditions.

Add to this a built-in cross-ventilated rainscreen behind the cladding: this feature creates a drainage and ventilation space to promote drying from the bottom of the wall all the way up to the roof peak — reducing moisture risk, mitigating condensation, and supporting long-term wall health.

Finally, the X-Bracket System is pre-engineered to handle extreme wind loads (even in high-wind zones), supports a range of insulation depths, and installs using common tools — so no specialized framing skills or unique hardware are required.

In short: it’s a “plug-and-play” continuous insulation system aligned well with high-performance building goals — exactly the kind of innovation the EEBA community supports.

Why the X-Bracket System Matters: Performance, Comfort & Durability

Thermal Performance and Energy Efficiency

Because the X-Bracket System eliminates thermal bridging, insulation performs far more effectively. Whether using spray foam or blown-in insulation, the continuous layer improves the whole-wall R-value. With the right bracket thickness and insulation density, teams can hit targeted R-values without needing excessively deep wall cavities. This is a big advantage when balancing energy goals with architectural constraints.

The improvement isn’t just theoretical. For homeowners like Brad, it translates into more stable indoor temperatures, reduced heating/cooling loads, and long-term energy savings. In tight-envelope, high-performance builds — especially in challenging climates — it’s a major win.

Moisture Control and Long-Term Durability

Continuous insulation with a ventilated rainscreen helps manage moisture risk — a frequent Achilles’ heel in high-performance, tightly sealed homes. The built-in cross-ventilated rainscreen provides a continuous drainage and ventilation plane behind the cladding to support drying and reduces the risk of trapped moisture.

Further, since the brackets themselves are not susceptible to rust or rot (unlike metal fasteners) and are engineered to last, the risk of failure over time is greatly reduced. For builders and homeowners who expect multi-decade performance from their envelope, this durability is a selling point.

Constructability & Labor Efficiency

One of the most compelling advantages — and the reason Brad was sold — is how straightforward the system is to install. X-Brackets attach to wood, steel, or even concrete surfaces with screws, nails, or adhesive (depending on substrate), and accept standard furring strips and cladding.

Because the system is pre-engineered (no job-specific structural calculations needed) and can withstand extreme wind loads, builders don’t have to worry about complex detailing or load-bearing failures. This reduces labor time, minimizes framing waste, and simplifies retrofit or new-build workflows.

For a retrofit — say, upgrading an older home’s envelope — X-Brackets can transform a messy, labor-intensive job into a streamlined installation with fewer trades, less waste, and better performance.

Versatility Across Applications

Another strength of the X-Bracket System is its flexibility — it can be used not only on exterior walls but also on roofs, basements, concrete walls, floors, and even shipping containers. This makes it a powerful tool for a wide variety of building types and retrofit scenarios.

The ability to leverage either spray foam or blown-in insulation also gives builders flexibility to match budget, performance targets, and preferred workflow.

Why High-Performance Builders & EEBA Members Should Care

As members of the EEBA community know all too well, succeeding in high-performance building isn’t just about hitting R-value targets or airtightness numbers — it’s about balancing performance, durability, health, constructability, and cost. The X-Bracket System is one of those rare solutions to check multiple boxes.

-

Continuous Insulation Without the Thermal Penalty: Traditional CI systems sometimes impose constraints — thicker walls, complex detailing, thermal bridging, or cladding-attachment headaches. X-Brackets let you get CI’s benefits without those downsides.

-

Moisture & Durability Built In: The combination of non-corrosive, rot-resistant brackets plus a cross-ventilated rainscreen reduces long-term maintenance risk — a compelling advantage for climates with freeze-thaw cycles, seasonal moisture, or swing temperatures.

-

Constructability + Speed + Flexibility: Whether you’re doing a deep energy retrofit, building new, insulating a basement or a shipping container, or upgrading a roof — this system adapts. That flexibility is especially valuable at a time when workforce shortages and labor costs are significant constraints in residential construction.

-

Cost-Effective Trade-offs: Because X-Brackets allow builders to meet performance goals without gigantic wall assemblies or deep framing bays, you may save on materials, labor, and time — making high-performance retrofits or CI-driven new construction more economically viable.

In short: for builders, architects, and remodelers committed to high-performance, resilient, durable homes — the X-Bracket System offers a realistic, proven path forward.

Addressing Common Questions & Misconceptions

Does using X-Brackets inherently mean expensive spray foam? Not necessarily. Spray foam appears to cost more when comparing to foamboard or rockwool, but the cost of spray foam factors in both labor and material costs, not just material. The InSoFast Team is also excited to release the new Batt – Bracket in January 2026 to further extend options to batt insulation.

How do you ensure moisture control / avoid condensation? The built-in cross-ventilated rainscreen provides a continuous drainage and ventilation plane behind the cladding; when combined with proper WRB and installation practices, this supports drying and reduces risk of trapped moisture. Adding continuous insulation on the outside of the wall eliminates the risk of condensation in the wall cavity.

Is the system robust enough for roof or floor applications (not just walls)? Yes — X-Brackets are engineered for multiple applications: walls, roofs, basements, floors — even shipping containers. For floors, the system can help soften slab floors, improve thermal separation from concrete, and even support radon mitigation when closed-cell spray foam is used.

Conclusion: The X-Bracket System — A “Win-Win” for Performance and Practicality

For Brad — and for builders like us — the X-Bracket System bridged a gap many insulation solutions struggle with: how to deliver true continuous insulation, high R-values, moisture control, and long-term durability, without sacrificing constructability, labor efficiency, or cost-effectiveness.

In the world of high-performance building — where every detail counts, and where success depends on balancing building science with real-world constraints — this kind of system matters. For retrofit projects, renovations, new builds, or unusual applications (shipping containers, basements, garages), X-Brackets bring flexibility. For clients demanding energy savings, comfort, and resilience — they deliver performance. For builders, they offer simplicity, speed, and peace of mind.

If we want to push residential construction forward — toward homes which are more efficient, durable, healthier, and easier to build — systems like X-Bracket deserve a hard look.

Next Steps & CTA

If you’re exploring continuous insulation strategies for your next build or retrofit — or you’re struggling with thermal bridging, moisture risk, or labor-intensive CI details — consider evaluating the X-Bracket System as a practical, high-performance solution. Feel free to reach out if you’d like help modeling performance, designing the assembly, or planning an install.

Learn More: InSoFast.com